It is understandable if the few of you who do sometimes visit this blog thought that we'd shut down, I must admit this is due to the fact that there wasn't much time for any work on project UAV since the summer holidays. However since exam season finished and I got my last cheque from the Arkwright Scholarship I decided that I owe it to the project to make some progress.

It is understandable if the few of you who do sometimes visit this blog thought that we'd shut down, I must admit this is due to the fact that there wasn't much time for any work on project UAV since the summer holidays. However since exam season finished and I got my last cheque from the Arkwright Scholarship I decided that I owe it to the project to make some progress.So I bought some components and did a little tinkering. Here are the results...

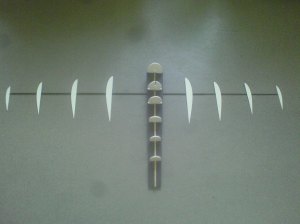

As you can see, in the world of amateur UAV design, size matters.

The 70mm diameter ducted fan at the bottom of the pic, produced quite a kick but wasn't anywhere near enough for the airframe. As of such I had to upgrade to the 340mm outboard prop to produce any reasonable thrust. Hopefully I should have some bench test vids up on the blog a little later.

So I suppose what one should take away from this is the fact that a cause is never lost as long as you keep fighting for it.

This UAV will fly someday and with my current burst of enthusiasm I am hopeful for a flight some time next feb. Fingers Crossed.